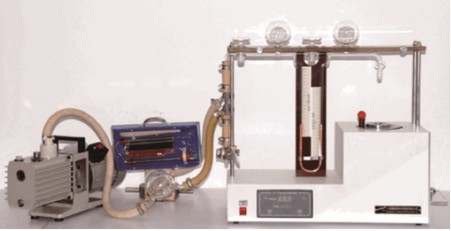

SF-1 Pressure Difference Moisture Determination Device

Moisture determination by the pressure difference method uses a pairing method. Various known moisture contents are respectively used to examine and determine the different D, E liquid level rises or falls correspondent to different moisture contents. Therefore, when substances with unknown moisture contents are examined, their moisture contents may be determined according to the different D, E liquid level rises or falls.

Domestic manufacturers frequently apply this method to determine water contents of dried polyester slices and nylons, under a general examination temperature at:

Polyester chip 220±5˚C

Polyamide 6, 66, 69, 610, 612 195±5˚C

Polyamide 11, 12 170±5˚C

Technical Specification

• Measuring part

Measurement part is shown in figure 1; it is composed of a set of glass structure, a vacuum pump, and a vacuum gauge; and a very good air tightness of the entire structure is required. The vacuum pump enables measurement part reach a high degree of vacuum prior to testing.

• Heating part

It is composed of a heater, a hearth and a lift platform with a cuvette suspension centering device. When the lift platform is raised up and a

Temperatures are controlled by a single-chip microcomputer. Through slight touch switches, higher temperature control accuracies can be reached.

• Technical data

Moisture ratio:

(5~500) ppm (when the test sample weighs 3g)

(30~3000) ppm (when the test sample weighs 0.5g)

Corresponding measurable highest water content: 1.5mg

Temperature range: (50~250˚C)

Reading error: ±3˚C (170˚C, 195˚C, 220˚C)

Temperature fluctuation: ±2˚C