YG368 Automatic Yarn Crimp Contraction & Shrinkage Tester

In testing process, there are functions of automatic changing load, adding load, automatic timing, automeasure length and automatic calibrate zero. Test results are automatically computed and printed.

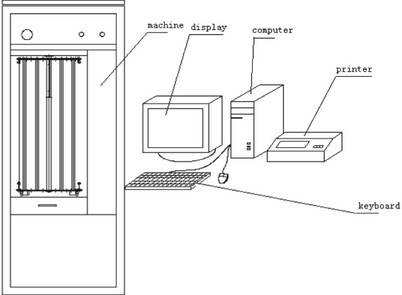

The instrument consists of six parts: oven, electronic balance, test stands, industrial computer and printer. The appearance is like picture 1.

The main technical parameters are as follows:

1. Load force: 2.5-5000cN (arbitrarily set & automatically applied),

2. Sample length: 1000mm

3. Length resolution: 0.04mm

4. Test indicators: Crimp contraction CC (%), Crimp modulus CM (%), Crimp

5. Data input: Via keyboard and mouse

6. Data output: Screen display, printing by printer

7. Number of test samples at one time: 30

8. Power:220V,50HZ ,0.5KW, oven:4.8 KW

9. Compressed air: (0.4-0.8)Mpa

10.Data storage and query

Main Features

1. It is controlled by IPC and enhances the reliability of the whole machine.

2. It uses imported high-precision electronic scale which helps to get high

4. The software can automatically change parameters according to user's

5. Instrument can be easily connected to Internet with a network card

Crimp contraction, crimp modulus and crimp stability are calculated from the measured lengths using the following formulas:

Crimp contraction CC(%) = [ (Lg - Lz) / Lg ]×100%

Crimp stability CM(%) = [ (Lg - Lf) / Lg ]×100%

Crimp modulus CS(%) = [ (Lg-Lb) / (Lg-Lz)]×100%

For optimum development of the yarn crimp, the yarn hanks are subjected to a thermal treatment prior to test start.

It is a test instrument for fully automatic length measurements on yarn hanks, characterized by its high flexibility in terms of test sequence configuration, choice of measuring loads and time-intervals for the loading- and unloading periods.