Chips dryer for textile

Features of chips dryer

crystalline and amorphous chips can be dried, due to incorporated crystallizer

crystalline and amorphous chips can be dried, due to incorporated crystallizer

low energy consumption, also at reduced capacity

low energy consumption, also at reduced capacity

high flexibility 40-110% without mechanical modification

high flexibility 40-110% without mechanical modification

residual moisture of chips as low as 15ppm

residual moisture of chips as low as 15ppm

extremely sharp hold up spectrum ensures the same treatment for all chips

extremely sharp hold up spectrum ensures the same treatment for all chips

drying by hot dry air, no nitrogen required

drying by hot dry air, no nitrogen required

heat recovery is not required, due to special design

heat recovery is not required, due to special design

no maintenance and no cleaning required for the dryer

no maintenance and no cleaning required for the dryer

no cooling water required, due to special design

no cooling water required, due to special design

continuous operation, throughput is controlled by extruder

continuous operation, throughput is controlled by extruder

large number of sizes allows optimum selection of dryer

large number of sizes allows optimum selection of dryer

closed air circuit

closed air circuit

Process description

Chips dryer is a hopper or solid-bed dryer with integrated crystallizer. The upper part is equipped with a chips lifter. The chips lifter keeps the chips moving, not allowing them to stick together during heat up. The chips are flowing through the dryer forced by gravity. The filling of the dryer can be done by several methods according to customer request and available space. The drying is effected by hot dry air which passes through the dryer in opposite direction to the chips. The dried air has a dew point below -40°C which is generated by an Adsorption Air Drying Unit. The air is circulated in a closed circuit by Roots blowers. There is no intake of fresh outside air, therefore only moisture has to be removed from chips which improve the economy.

The air leaves the dryer at the top, passes a cleaning system to separate the dust, and is returned to the blowers and air drying unit. The air required for the heating and drying of chips can be recycled completely or partially. The humidity of dry air is measured continuously.

Cooling of air is not required resulting in reduced energy consumption. Cooling water is not required.

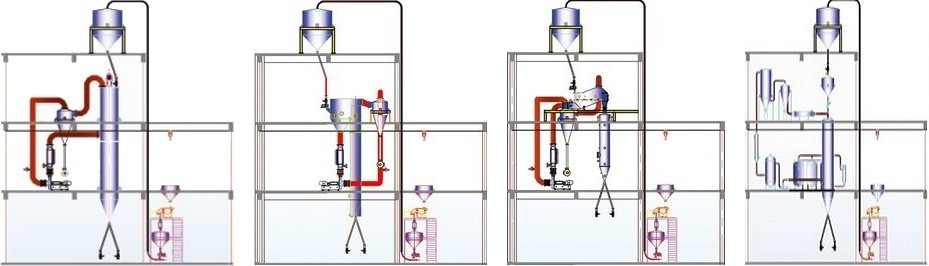

Types of chips dryer

KF Drying System,

KF Drying System,

FRS Drying System,

FRS Drying System,

FBM Drying System

FBM Drying System

Applications

Drying of polyester chips or polyamide chips down to 15ppm moisture for:

textile filaments

textile filaments

micro filaments

micro filaments

staple fiber

staple fiber

technical yarns

technical yarns

POY, FOY, FDY

POY, FOY, FDY

Non woven spinning

Non woven spinning