Procedyne fluid bed

Highly efficient cleaning process having excellent heat transfer properties similar to a liquid bath by the application of fluid bed principals for safe cleaning of assembled tooling with no danger of potential damage to the hardware.

The uniform grain size alumina oxide media particles- non toxic-non flammable - chemically & physically inert - does not melt or degrade, offer high usable temperature value, reusability over & over again due to infinite life. Minimal operating cost due to low consumables and flexibility to switch-off the system when not in use, making it a low energy & economic operation.

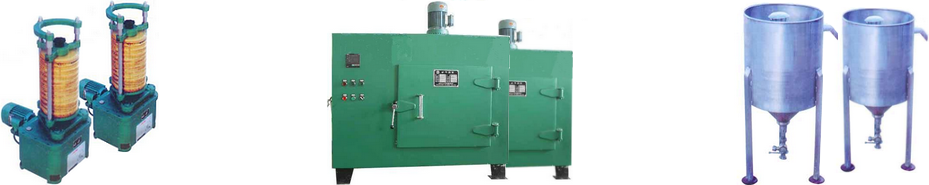

We also provides Alumina sand cleaning, drying and sifting equipments.

Model |

Dimension

Dia×H |

Efficient Volume

L |

V/KW |

Work pressure

MPa |

Air consumption

L/h |

YF-1 |

φ450×800 |

100 |

380/18 |

0.4 |

18 |

YF-2 |

φ520×1000 |

180 |

380/21 |

0.4 |

18 |

YF-3 |

φ620×1200 |

320 |

380/27 |

0.4 |

20 |

The process is as follow. First putting spinnerets/spin pack/filter core,etc.. in boiling solution which contents NaOH(15-20%) for 2 to 3 hours to remove most polymer, then in TEG bath at the temperature up to 280℃ for about 12 hours. After cooling it, it is rinsing sequentially in alkaline solution, water and ultrasonic tank before drying and storing it up.

Single, double or multi-tanks are provided. The platform is equipped when using large tank diameter and high operation height. There are three choices for open/close furnace cover: pneumatic, heavy lifting device and screw device. Temperature automation control device is equipped with Japan Fuji temperature control unit and solid-state relay. All the controlling parts are made according to the requirements of anti-explosion in order to guarantee stable and reliable performance.

We also provide sequential rinsing equipments, such as water cleaner, alkali cleaner, ultrasonic cleaner, etc..

Model |

Dimension

Dia.×H |

KW

Voltage/KW |

Temperature Precision |

Work hour |

RTL-3 |

φ320×800 |

380V/9KW |

±1℃ |

≤8h |

RTL-4 |

φ420×900 |

380V/12KW |

±1℃ |

≤8h |

RTL-5 |

φ500×1000 |

380V/24KW |

±1℃ |

≤8h |

RTL-6 |

φ650×1200 |

380V/32KW |

±1℃ |

≤12h |

RTL-8 |

φ800×1200 |

380V/54KW |

±1℃ |

≤16h |

RTL-10 |

φ1000×1800 |

380V/63KW |

±1℃ |

≤16h |

RTL-12 |

φ1200×2500 |

380V/98KW |

±1℃ |

≤16h |